XPS Margin Recycle Machine

XPS recycled machine, EPS recycled, recycling machine

Nowadays, people care more about environment protection.

During production of XPS Foam Board, there will be waste of cut edges and powder. Our XPS Margin Recycle Machine is designed to recycle those edges and powder. The white EPS foam is recyclable by this machine also.

1. Support the XPS margin board.

2. Compact design

3. Filter screen changeable

4. Single screw extruder

Specification |

Crash Motor | 7.5KW,980rpm

AC/380V/50HZ | |

Extruder Motor | 7.5KW,1440rpm

AC/380V/50HZ | |

Meterial | Screw: 38CrMoALA

Barrel: 38CrMoALA | |

Output | 60-100 kg/hr | |

1. Main unit

2. Cooling water tank

3. Pelletizer

Advantage from Feininger XPS production line |

What does the machine do?

Waste powder will be completed heated, melted and well mixed inside of the machine. After filtering process, the melt materials will be pushed forward through a Mould, from where strings of polystyrene are shaped. The hot strings will then go through cooling water to a Pelletizer, here granule is made.

The whole process is simple, safe, eco-friendly and most importantly, saving your dollar, as the granules are 100% reusable in XPS production.

What is our design ideal?

Stability, Efficiency, Saving Energy, Environmental Protection.

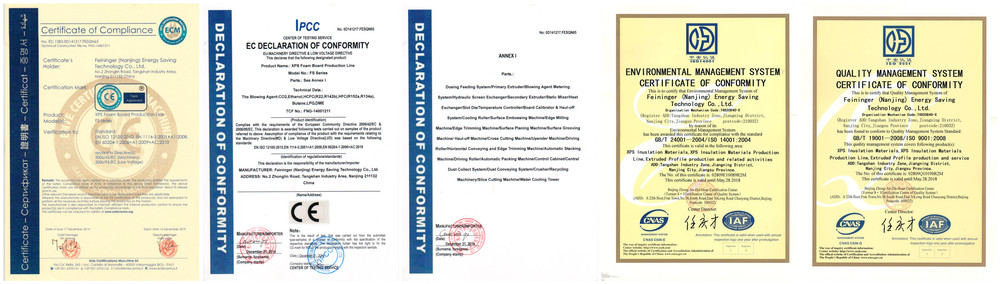

Why choose Feininger?

1. We are the strongest XPS supplier, produce the NO.1 class XPS board by our own machinery.

2. Specialist in XPS industry, more than 10 years practice experience.

3. Professional R&D center and service support team.

4. More than 500 lines Successful running line around the world.

5. Lowest Energy consumption.